|

President’s Word

We are definitely in the right industry!

Pierre Pienaar*

We are fast approaching 2 years into the

pandemic and the packaging industry remains in the spotlight as we continue to search

for innovative solutions to sustainable packaging and e-commerce design

demands. Across the world the human spirit has been amazing as we find ways to re-establish

the industry to a new normal. We are fast approaching 2 years into the

pandemic and the packaging industry remains in the spotlight as we continue to search

for innovative solutions to sustainable packaging and e-commerce design

demands. Across the world the human spirit has been amazing as we find ways to re-establish

the industry to a new normal.

The pace of global change is increasing,

creating uncertainty about the consumer preferences and behaviours that will

affect the future of the packaging industry.

Here are some recent developments:

- There is a need for new and recycling and

processing technologies, that can be commercialised, implemented, and promoted,

if sustainability requirements are going to be met.

- We will continue to see shifts in our

industry and it will mean that companies, brands, manufacturers, and retailers need

to adapt to this ever-changing landscape over the coming year.

- There will be a need for packaging

manufacturers and brands to develop and commercialise recyclable package

innovations although in many cases the capabilities to recycle them do not yet

exist.

- There is talk that sustainable packaging

will be superseded by ‘responsible’ packaging, thus taking a more practical

approach where brands can promote, and consumers can understand and act upon.

- There is more pressure on non-recyclable

plastics packaging consumption which hopefully will result in more easily

recyclable and sustainable packaging materials such as recycled PET as well as paper

and board, not forgetting a reduction in excessive secondary packaging.

- Rising real incomes in Asia and other

developing regions will see more spending on packaged products, including food,

luxury products and cosmetics.

- Flexible packaging to replace traditional

packaging, where high-barrier films and retort stand-up pouches will replace

rigid pack formats, such as metal tins and glass jars, for a wide range of food

products.

- Consumer demand for convenience in food

should show an increase in consumption of microwavable ready meals, more

portable packaging, packaging for on-the-go consumption, and convenience

features, such as easy-open and reseal components.

The packaging industry continues to grow at

an alarming rate across the world. Smithers recently released their forecasts predicting

that the global packaging market is to reach $1.05 trillion in 2024. We

certainly are in the right industry for growth but at the same time we need to

be mindful that the packaging produced must align with, as well as meet, the global

sustainable guidelines.

The WPO along with ECR Community (Efficient

Consumer Response) in Europe, has just released (4 October 2021) a Global Circular

Packaging Guide. This will certainly assist all countries to meet their

packaging obligations in the sustainability world.

My thoughts are with those affected by the

virus around the globe. On behalf of all at the WPO, I wish you, good health

and safety. Take care and best wishes.

*Pierre Pienaar is President of WPO

[email protected] [email protected]

WPO – World Packaging Organization

WPO – World Packaging Organization

pienaarpierre

pienaarpierre

@WorldPackOrg1

@WorldPackOrg1

From the Editor

Responsibility is the next sustainability

By Liliam Benzi*

With these words - Responsibility is the next sustainability

- David Luttenberger, from Mintel's Packaging Trends team, opened the

presentation of a sustainability report in Latin America. According to him, to

change 'sustainability' for 'responsibility' - and therefore 'sustainable' for

'responsible' and 'sustainable packaging' for 'responsible packaging' - is

justified because the term sustainability has been overused and used

incorrectly to the point that final consumer is questioning its credibility.

In addition, the consumer tends to understand more clearly

what it means to be responsible; the concepts contained in sustainability end

up generating some confusion. And, unfortunately, some companies do not

contribute to dispel these doubts; on the contrary, they create a smokescreen

with the term, 'marketing' it.

Another important point is that today, consumer values

'small actions' more than 'big claims'. So, instead of trying to impact the

consumer in a meteoric way, genuine changes towards sustainability of brands,

products, and packaging, must be reflected in concrete and easily perceptible

results.

Mintel's experts agree that consumers have no intention of

eliminating packaging; what they expect is access to environmentally, socially,

and economically optimized packaging. And the companies that, in addition to

this real optimization, manage to create empathy with the consumer, via

packaging, showing that the product and the brand are really there to help them,

will come out ahead. On this same trajectory passes the consumers education process.

Another relevant point raised in Mintel's survey is that

consumers are seeing more clearly the relationship between climate change and

their purchasing options. In Brazil, for example, 77% of consumers agree that

climate change will have effects on the food and beverages they consume. With

this, they will increasingly seek to be more responsible and buy brands aligned

with this purpose of responsibility.

Going a bit further, it was clear that consumers find it

cool that companies show respect for the environment. But the question at the

end of the day is: what are you really doing to help me be a more responsible

consumer? As said, the consumer wants to turn sustainable into something

'action-able' and personal.

At this point, comes the concept of 'carbon handprint', in

allusion to the 'carbon footprint', which definitely has a more personal

footprint. While responsibility is a more intuitive concept for consumers, the

'carbon handprint' is related to actions where the consumer can evaluate the

footprint of the goods and services he buys and uses. It is the company - and

the packaging - helping them to become more responsible and thus more

sustainable.

In the LATAM universe, Brazilian consumers are years ahead

on truly sustainable demands. Mintel research shows that they simply won't

commit to quality or familiarity with sustainability; they expect concrete action.

As the three big topics of this new responsibility, Mintel suggests:

- responsibility/sustainability is not an all or nothing

proposition;

- packaging is not the enemy;

- it takes empathy and education to make a real difference.

It is also positive to realize that even during the

pandemic, the environmental issue remained alive in the consumer's mind, and I

dare say that in many cases it became more alive since people had more time and

more information to think about it.

And this thinking comes in handy with the legislation and

recycling labels that are popping up more and more in Latin America and that

draw attention to the disposal of packaging. In tow comes an avid consumer for

eco-friendly packaging, but again, they really need to understand

what this means and they don't want to feel lost amidst far-fetched concepts

and terminology.

About being recyclable or having recycled content, Mintel

research indicates that the idea of recyclable is more aligned with current

consumer expectations of helping the environment. If this is the case and you

work with recycled content, make it clear, as much as possible, that recycled

content does not mean, necessarily, being recyclable.

People react - and believe - what they see, so it is up to

companies to prove what they are doing. Here arises the principle of 'show and

tell' design - show from a beautiful design but explain, so that the consumer

can understand, and use icons that are consolidated and endorsed by recognized

bodies known by this consumer.

We definitely live in an era where conscious consumerism

will dictate the new rules and where an 'eco responsible' packaging will be

protagonist as long as it is equally accessible and fits in the budget. A

tangible packaging in all senses.

For companies, here's a tip: simplify your speech, present

clear metrics, and prove that there is a positive personal impact on your

products, packaging, and branding!

*Liliam Benzi is WPO Press & Communication Liaison

Officer and runs its own Communication & Strategy company for the packaging

industry, LDB Comunicação Empresarial.

[email protected] [email protected]

(+ 55 11) 99989-1597 (+ 55 11) 99989-1597

liliambenzi liliambenzi

liliam-benzi-870b771a liliam-benzi-870b771a

Liliam Benzi Liliam Benzi

Message from General Secretary

We will meet again soon!

Writing this article, I’m still a bit enthusiastic:

I’ve been to a trade show last week. About packaging. In Germany. With real people,

having real discussions. Meeting nice friends from Europe, having coffee with

them. A stage program with at least half of the speakers doing live

presentations (Nerida: Ok, Australia was too far away, but very good to have

you there virtually!).

I’m talking about Fachpack

(www.fachpack.de/en), the packaging show of NürnbergMesse. Smaller than in

other years, for sure, but very crowded. They were running a detailed hygiene

concept to fight Covid (vaccination, testing, masks, distance, and comprehensive

online tools). Nobody knew in the days before the show, but it was a big

success. I can’t describe that feeling of absolute happiness for me as

participant. WPO joined the EPIC area there and we organized a presentation

slot on stage.

What I want to say: we will meet again, in

person, in a near day! It’s necessary and it will be good!

Meanwhile, according to the actual

Covid19-Situation our WPO Board Meeting in November 2021 will be held virtual

again. The WPO Meeting program will start on Monday, 22nd of November with the

Executive Meeting (restricted to the executive members of WPO only). On

Tuesday, 23rd of November, you are invited to take part in our parallel working

group meetings and a webinar on packaging recycling in Indonesia and our new

guideline for recycling. The World Star Judging will be done on Wednesday, 24th

of November. Our crowning finale on Thursday, 25th November will be the WPO

Board Meeting.

Soon, you will get the invitation by email

with all the links and agendas of the meetings. Please prepare properly for the

meetings, as our time there will be limited again, as in the last virtual

sessions. But I guess, we are all experts meanwhile in doing it that (zoom)

way!

One important thing to mention left: since

mid of September, Tanja is on her maternity leaf. All runs well for her

personally so far (and I won’t make jokes about that big, special pack she has

to deliver soon …). The handover process to Ulla run well and she is handling

the WPO Secretariat like a long time professional. It’s time to get to know her

a bit better. Ulla, your stage:

“Hello everyone, I am 24 years old and I'm

originally from Bavaria, but now I've fallen in love with beautiful Vienna and

the good coffee. I am really looking forward to the new tasks and even more

when we, hopefully, can all meet in person. If you have

any questions or problems, please feel free to contact me.”

Thx, Ulla! So, if you have any questions

about the upcoming meeting or anything else, just contact us via any channel

you prefer! Otherwise, see you soon at our meetings in November!

Ulla Hruschka & Barbara Zottl

WPO Secretariat

[email protected]

Johannes Bergmair

WPO General Secretary

[email protected]

Around the World

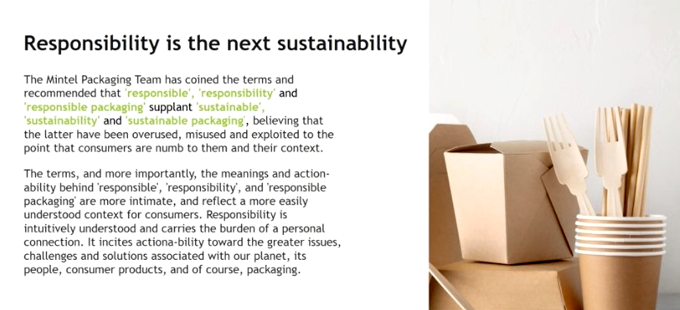

Competition for the best packaging in Ukraine

In April 2021, competitions for the best packaging and label

were held in Ukraine, organized by local WPO member, the Club Packagers of

Ukraine (www.upakjour.com.ua or www.packinfo.com.ua). 47 samples, from 23 Ukrainian companies,

representing 10 cities, took part in the competitions.

The jury consisted of well-known experts in Ukraine and

abroad, headed by Valery Krivoshey, Honorary President of the Club Packagers of

Ukraine. 23 packages were awarded with the ‘Ukrainian Packaging Star’ and 4

labels were winners of the ‘Ukrainian Label’.

At the same time, it was held a competition among young

designers, the ‘Packaging of the Future’ with the participation of 45 packages

and labels, presented by students from 9 academies. The first 03 places were:

Zoryana Ostapets, Luka Shavdatuashvili and Polina Makarenkova, students of the

National Academy of Fine Arts and Architecture. They are all students of

Professor Vitaly Shostya.

The competition was supported by Flexores, Geidelberg,

UkrPEC and the Union of Designers of Ukraine. The awarding of the winners took

place on June 3, 2021. An all winners are eligible to WorldStar, WPO global

packaging competition.

For more information, contact Veronika Khalaydzhi ,

President Club Packagers of Ukraine by e-mail [email protected].

In Spain, Liderpack awards is on!

Organised by WPO member, Graphispack Asociación (www.graphispack.org) and Fira de Barcelona's

Hispack trade fair, the Liderpack awards are the most important prizes awarded

in Spain in packaging and POS material. The local packaging industry joins

more than 2,100 companies that employ 74,000 workers. Organised by WPO member, Graphispack Asociación (www.graphispack.org) and Fira de Barcelona's

Hispack trade fair, the Liderpack awards are the most important prizes awarded

in Spain in packaging and POS material. The local packaging industry joins

more than 2,100 companies that employ 74,000 workers.

Annually the award promotes and recognises the innovation

and creativity of these companies and professionals. The jury is formed by

professionals and experts from various areas such as packaging, POS, design,

logistics, marketing and advertising compose the jury.

The Liderpack 2021 award ceremony will take place during

Hispack on May 2022 at Fira de Barcelona's Gran Via venue.

For more information, contact Vanesa Armijo, Commercial and

Events Director of Asociación Graphispack by e-mail [email protected].

WPO presents at the Brazilian Packaging Congress

WPO supported the Brazilian Packaging Congress, organized by

its local member, ABRE (Brazilian Packaging Association – www.abre.org.br) that brought together packaging companies,

businessmen from the consumer goods and digital retail industries, and experts

from the international scene to debate the transformation of the consumer

market, consumer, and dynamics of retail and its reflexes for the brands and

the packaging industry.

Based on the central theme “The role of packaging in the new

challenges for Brands”, the Congress aimed to promote the discussion about new

perspectives of competitiveness and construction of value in the consumer

market, placing the future at the center of business, discussing the

transformations and its consequences for the entire packaging and consumer

goods chain.

On a global level, this edition counted with the support of

the WPO and one of its members, the Argentinian Institute of Packaging (IAE – www.packaging.com.ar). Among the keynote speakers, Pierre

Pienaar, President of WPO, delivered the opening speech.

Packaging as part of the Milan Design Week

For the occasion of the Milan Design Week (Sept 04-10), the

Italian Packaging Institute (www.institutoimballaggio.org),

a WPO member and promoter of the Best Packaging contest as a program of the

Ethical Packaging Charter Foundation (www.fondazionecartaeticapackaging.org),

organized a show that intended to lead the world of packaging design and

business, through a dialogue between ethics and technological innovation.

The heart of the project was the interpretation of the 10

values of the Packaging Ethical Charter: responsible, balanced,

safe, accessible, transparent, informative, up-to-date, forward-looking,

educational and sustainable. Each of the 27 finalists competing for the Best

Packaging 2021 award designed their own packaging by finding inspiration in the

10 values.

The exhibition concept was an imaginary dialogue between the

storytelling of the 10 values, by the shots of the photographer Claudio

Bonoldi, and the finalist projects of the Best Packaging 2021 contest. The

visitor was led inside a path, made of suggestions and objects representing

daily life. The exhibition also aimed to show the design steps of the packaging

solutions.

The result was a synthesis between the ideal and the real;

the desire to achieve a hypothetical perfection and the needs of safety,

hygiene, protection, transport, communication and service that packaging should

provide.

According to Anna Paola Cavanna, President of the Italian

Packaging Institute and the Ethical Packaging Charter Foundation, “packaging is

an essential part essential of our life and allow us to enjoy goods and

services. And it is also always under close observation, for the legislation,

for the aspects of sustainability that cannot be postponed, and for the

continuous solicitations of the market and consumers. The excellent result of

this contest is an example of how companies are ready to respond to new

challenges, especially in terms of eco-design. We understand that companies

need precise guidelines for a clear and complete communication with citizens."

AIP releases ‘Sustainable Packaging Design Case Studies’ for

the industry

WPO member in Australia, AIP (Australian Institute of

Packaging – www.aipack.com.au) is pleased to announce the

development of a series of Best Practice Award-winning examples of innovative

Sustainable Packaging Design from across Australia and New Zealand.

All of the case studies have been recognised in the annual

Australasian Packaging Innovation & Design (PIDA) Awards and over 95% have

gone on to receive global recognition for their innovative Sustainable Packaging

Designs through the WorldStar Packaging Awards. Some of the ANZ winners have

also received this global packaging award organized by WPO.

The AIP Sustainable Packaging Design Case Studies are

available at http://aipack.com.au/pida-awards-sustainable-packaging-case-studies/.

Marina Altayó is the new President of Graphispack Marina Altayó is the new President of Graphispack

On June 21th, the virtual Ordinary General Assembly of the

Graphispack Association, WPO member in Spain, elected Marina Altayó, Sales

Director Southern Europe at XSYS Global/Flint Group Iberia, as President. The

new Board is formed by: Marina Altayó (President), Javier Riera-Marsá (Vice

President), Jordi Quera (Vice President), Carlos Aguilar (Treasurer) and Manuel

Julián (Secretary).

The new president of the Spanish Packaging Association, also elected in this occasion, is Julio Berdún from Markem Imaje.

For more information, contact Vanesa Armijo, Commercial and

Events Director of Asociación Graphispack by e-mail [email protected].

AIP representative on newly-formed ANZPAC Collective Action

Group (ACAG)

The Australian Institute of Packaging (AIP – www.aipack.com.au), a WPO member, is pleased to announce that

the Institute has a representative on the ANZPAC Plastics Pact newly-formed

Collective Action Group (ACAG), Nicole T Garofano. The Australian Institute of Packaging (AIP – www.aipack.com.au), a WPO member, is pleased to announce that

the Institute has a representative on the ANZPAC Plastics Pact newly-formed

Collective Action Group (ACAG), Nicole T Garofano.

The ANZPAC Plastics Pact (ANZPAC) is a collaborative

solution that brings together key players behind a shared vision of a circular

economy for plastic, where plastic never becomes waste or pollution.

Together through shared knowledge, investment and industry

led innovation the purpose is to implement solutions tailored to Australia, New

Zealand and the Pacific Islands region.

ANZPAC is the first in the Oceania region and second

regional Plastics Pact to become part of the Ellen MacArthur Foundation’s

global Plastics Pact network, with Pacts in Africa, Europe, Latin America and

North America. As an international challenge, Plastics Pacts address the

transnational nature of the issues related to managing plastic by providing a

consistent approach for global supply chains dealing with plastic waste

travelling across our borders, moving from a linear approach to a circular

economy for plastic, in which it never becomes waste or pollution.

"Being accepted as a member of the ANZPAC Collective

Action Group (ACAG) as a representative of the AIP for Australia and New

Zealand is such a privilege and a thrill”, states Nicole T Garofano. And adds:

“This opportunity extends my commitment to create change in the way plastic

packaging is generated and managed in the ANZPAC region. My goal is that

through AIP representation on the ACAG, members’ expertise can be shared to

support the achievement of Pact targets. The collaborative value of being part

of the ANZPAC Plastics Pact will also become evident. Having AIP on the ACAG

invites industry innovation to support the ANZPAC value chain to further the

achievement of a circular economy for packaging in this region.”.

For more information on the ANZPAC Plastics Pact visit www.anzpacplasticspact.org.au.

From the Board

WPO recognised the ‘International Day of

Awareness of Food Loss and Waste’ on 29 September

The ‘International Day of Awareness of Food

Loss and Waste’ was designed to make a clear call to action for both the public

and private sectors to prioritise actions and move ahead with innovation to

reduce food loss and waste.

“It is known that 1/3 of all food produced

in the world is wasted and when food is lost or wasted, all the resources that

were used to produce this food - including water, land, energy, labour and

capital - go to waste. Environmentally food that is lost or wasted is

responsible for 8% of global greenhouse gas emissions. If food waste were a

country, it would be the third largest GHG emitter behind the USA and China”,

explains Pierre Pienaar, WPO President. According to him, “packaging can play

an integral role in minimising food waste at the start of the value chain so

that waste can be prevented in the households”.

“Avoiding food waste is a critical

packaging issue and one that food producers, manufacturers, brand owners,

retailers and consumers need to better understand. Without adequate intuitive

packaging design features and fit-for-purpose packaging, food can potentially

be wasted all the way through the supply chain to the consumer. By modifying

packaging designs and ensuring that Save Food Packaging Guidelines are followed

food waste and loss can be minimised and/or prevented”, completes Nerida

Kelton, WPO Vice President Sustainability & Save Food.

Both WPO Executives agree that the most

innovative and intuitive Save Food Packaging uses design features that can

contain & protect, preserve, extend shelf life, easily open and reseal,

provide consumer convenience and portion control; all the while meeting global

sustainable packaging targets.

Opportunities for packaging design to

minimise food waste can include better facilitation or communication around

portion control, date labelling, extension of shelf life, protection,

resealability and openability, serving size, food safety/freshness information,

information on storage options and improved communication on packs.

WPO has been working on the issue of Food

Waste and the role that packaging plays for many years now and as the

organisation developed a special award category for innovative and intuitive

‘Save Food Packaging Design’ in the annual WorldStar Packaging Awards. As Nerida

Kelton explains: “The Packaging that Saves Food Special Award is designed to

raise the profile of the critical role of packaging to reduce food waste and

therefore reduce product’s overall environmental impact and recognises

companies that are developing innovative and sustainable packaging that

minimises food losses and food waste, extends shelf life and improves the

supply of food. The WPO encourage all businesses to consider entering this

award category to help showcase Best Practice Save Food Packaging Design across

the globe.”

How to be part of the ‘International Day of

Awareness of Food Loss and Waste’ initiative?

“Begin in your own home”, advises Pierre

Pienaar, WPO President. To help with this, WPO has provided some ideas and tips

on how to minimise food waste at home.

- Learn the difference between A Use By date

and a Best before Date. Share this knowledge with your workplace, friends and

family

- Buy smaller packs that suit your household

numbers

- Plan Ahead and only buy what you need

- Don’t cook more than you need

- Buy resealable packaging

- Buy Freezer ready meals

- Look at innovative ways to use leftovers in

more meals

- Store Food in the right places e.g.:

freezer vs refrigerator vs room temperature

- Set your refrigerator to the correct

temperature

- ALWAYS donate extra food to neighbours,

friends or foodbanks

- Compost your food waste

- Get some chickens

- Nominate a few Meat Free Days during the

week

- Let the WPO know what steps you have made

to help minimise food waste in your home, work and extended family.

- Spread the message on social media #FLWDay

#reducingfoodlossandwaste #stopfoodwaste #savefoodpackaging

#worldpackagingorganisation

WPO prepared a special edition of ‘World

Pack Talk Show’, with Nerida Kelton, interviewed by Liliam Benzi, about the ‘International Day of Awareness of Food Loss and

Waste’. Access it at WPO YouTube

https://www.youtube.com/watch?v=IDfMju4EGzA&list=PLk84A5sL-GlEWGdKz0NQCppMNT-kOTgQ4&index=1

From the Market

Did you know that intuitive packaging can minimise

food waste?

The most innovative and intuitive Save Food

Packaging uses design features that can contain & protect, preserve, extend

shelf life, easily open and reseal, provide consumer convenience and portion

control; all the while meeting global sustainable packaging targets.

Opportunities for packaging design to

minimise food waste can include better facilitation or communication around

portion control, date labelling, extension of shelf life, protection,

resealability and openability, serving size, food safety/freshness information,

information on storage options and improved communication on packs.

Two stand out packs that were recently recognised

in the 2021 Save Food Packaging Design category, in the PIDA awards, organized

by WPO member Australian Institute of Packaging (AIP – www.aipack.com.au), were Junee Lamb for Agriculture and Edgell

Supa Crunch for Food Service.

Junee Lamb (Junee Lamb and Sealed Air for

CRYOVAC brand Total Bone Guard)

Meat products ending up in landfill

contributes to over 20% of the carbon footprint of total food waste. An

additional issue for meat products is leaking packs which causes unnecessary

food and water wastage. Product sent from Junee Lamb were arriving damaged at

the next point in the supply chain and non-conformance reports indicated that

lamb packaged in previous shrink bags were failing and yielding food waste in

the order of 4,300kg per week. The significant volume of water required to

produce the defective product was also being wasted in the previous packs. The

move to CRYOVAC TBG put an end to leaking packs, food and water waste for Junee

Lamb.

The vacuum shrink barrier bags are designed

to provide a significant shelf life of 90 days. This is particularly important

for the export market where long chilled shelf life is required. The design

provides tough puncture, tear and abrasion resistance, high oxygen barrier

properties, with built-in bone guard protection in areas that need it most. By

identifying the areas of the bag at risk of puncture/abuse (based on cut

packaged), bone guard can be purposefully positioned on the bag to protect

these areas. The 150um bone guard patch ensures the efficient use of materials

while delivering maximum protection and shelf life. The lamb will better

withstand the rigours of production, storage, and distribution and that also

means less waste. In this B2B application, multiple (up to six) meat cuts are

packed into CRYOVAC TBG vacuum shrink barrier bags driving better product:

packaging ratio and decreasing the amount of packaging used. The bag is

Australasian Recycling Logo (ARL) compliant and recyclable through soft

plastics collection programs.

Edgell Supa Crunch (Simplot Australia) for

Food Service

To meet the needs of the Foodservice

channel, Simplot developed Edgell Supa crunch, a new chip designed to stay

crunchy for up to 40 minutes throughout the challenging delivery process.

To complement and aid maintaining the crunch

during delivery, Simplot designed an innovative and sustainable pack that has a

raised and ventilated floor and just the right amount of ventilation on the

sides and top to allow steam condensate to escape while retaining heat.

This pack utilises the stack effect where

air is drawn into the carton at the base and then vents at the top of the

carton allowing moisture filled air from the chips to rise and escape. The

relatively shallow carton is designed to allow the chips to spread out, so they

are not on top of one another. The one-way venting that the stack effect

promotes works well in balancing heat retention and moisture escaping,

promoting quality for food delivery.

The product has instructions on the pack as

to how to use it, and how to effectively extend the life of the chips to keep

hot and crispy and therefore not wasted. This product has been designed to

extend the life of the product through keeping the product crispy and hot. If

the customer finds that the product has cooled too much the packaging has been

designed in a way that it can be reheated in a microwave for 20 seconds which

extends the life of the product reducing the risk of spoilage due to cold soggy

chips.

The pack was designed with tamper evidence

for product security and is stackable allowing for easier distribution of bulk

product and reducing the risk of crushing. The board is fully recyclable, FSC

certified and has been optimised to reduce the amount of board used.

Australian Food Waste strategy

The National Food Waste Strategy

(Australia), that aims to halve all food waste that heads to landfill by 2030, provides

a framework for collective action across the ecosystem. Packaging Technologists

have the opportunity to minimise food waste at the start by incorporating the AIP

Save Food Packaging Design guidelines into their NPD process.

Marketers can spotlight the SFP design

features as a point of difference and send a message to the consumer that the

brand is actively trying to minimise food waste from paddock to plate.

Embedding Save Food Packaging design

features at the NPD stage ultimately reduces the product’s overall

environmental impact at the start of the value chain, which minimises food

wasted in the household.

Thanks Nerida Kelton, Executive Director of

Australian Institute of Packaging (AIP) and WPO Vice President Sustainability

& Save Food, for contributing with this article. For more information,

contact her by e-mail [email protected].

Education

Packaging training programs continue a

total success

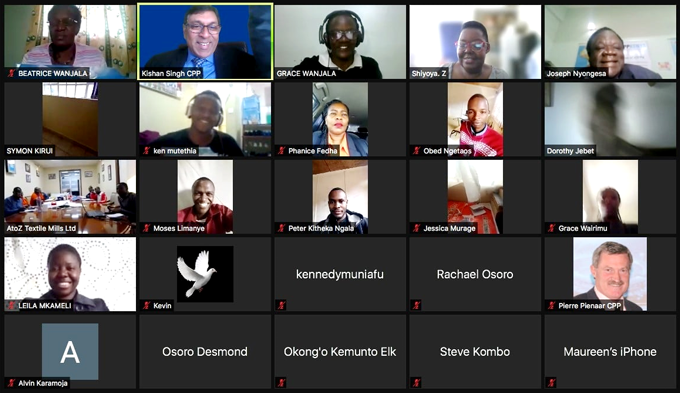

In August, WPO

sponsored the training ‘Packaging Design and Development for a Circular

Economy’ organized by its member IOPPK (Institute of Packaging Professionals

Kenya – www.ioppk.com) and supported by another WPO

member, APO (African Packaging Organisation – www.africanpackaging.org). Trainer was WPO

Ambassador, Kishan Singh, and there were 32 participants, including 10 from

Tanzania.

“The theme was chosen because environment

is an important issue in Kenya, particularly because the country is the

headquarters of UNEP (United Nations Environment Programme). The statement that

by 2050 the world will have more plastics in the sea than fish needs an urgent

response. WPO believes in the importance of educational programs on Packaging

Design and Development towards a circular economy and sustainable concepts”,

states WPO President, Pierre Pienaar. He also reminds that Packaging Education

is in the DNA of WPO´s strategy in order to guarantee “Better quality of life

through better packaging for more people „

Besides Kenya, WPO had a busy agenda of

training courses in the second half 2021, that included:

- Indonesia – WPO Masterclass Food &

Pharma Training – August

- Jordan – WPO Regional Packaging Technology

Training – September

- World – WPO Packaging Technology Training –

September

- Georgia – WPO Packaging Technology Training

– early October

The agenda also included a CPP (Certified

Packaging Professionals) Development Education & Training program scheduled

for October 2021. “The idea, in this case, is to train the participants on how

to become a CPP”, explains Henky Wibawa, WPO Vice President Education. CPP is a

certification created and licensed by WPO member in USA, IoPP (Institute of

Packaging Professionals).

For more information on WPO packaging

training programs contact Henky Wibawa by e-mail [email protected].

WorldStar

2022 WorldStar Packaging Awards is

open for entries

On June 9th, WPO (World Packaging

Organisation – www.worldpackaging.org) organised the

prestigious hybrid WorldStar Ceremony for 2021 winners, with over 250 people

attending, from 53 countries across the globe. The ceremony was co-hosted by

WPO President, Pierre Pienaar and Vice President Sustainability & Save

Food, Nerida Kelton.

During the ceremony, WPO announced 194

winners from 32 countries, including the winners of the Special Categories

(Marketing, Sustainability and Packaging that Saves the Food) and the

prestigious President’s Award. Furthermore, Ralph Moyle, CPP FAIP received the

Lifetime Achievement Award for 2021. The video of the ceremony can be accessed

in the YouTube link https://lnkd.in/dWVVp-G and all the list with

the winners is also available in the webpage www.worldstar.org.

After concluding the remarkable WorldStar

ceremony, WPO is happy to announce that the entries for WorldStar 2022 are open

until October 15, 2021. “We encourage every WPO member across

the globe to help us promote the largest and most prestigious global packaging

award. We are confident that we can even better the number of entries

registered in the 2021 edition: 345 from 35 countries”, states Pierre Pienaar,

WPO President.

Packages eligible for WorldStar are those

that have already received a national or regional packaging award recognised

by WPO. “In its 54th year, WorldStar is one of the major events

of WPO. As always, our aim is to promote packaging innovation in

various areas, proving that a good package can be an essential solution to many

of the modern problems, especially food safety, save food and sustainability”,

adds Pierre.

The schedule for the 2022 edition of

WorldStar Packaging Awards is the following:

- 15 October 2021 Closing date for entries

- November 2021 Judging Process.

- 15 December 2021 Announcements of results

- May 2021 Awards Ceremony and Gala Evening.

For general enquiries on the WorldStar

Packaging Awards contact Soha Atallah, WorldStar Coordinator [email protected] or visit www.worldstar.org.

WorldStar Student

Entries are open for the 2021 edition

Entries for the WorldStar Student Awards 2021 are open and

close on 1st November 2021. This international student award programme is a key

aspect of the WPO objective of 'Better packaging for more people" by

discovering and attracting talent into the global packaging industry.

The purpose is to expose students to the world of packaging

and the industry at large. Through participation, students tackle projects that

illustrate their potential and test the skills that are required for the art

and science of packaging. Students gain insight into the

role packaging plays in the supply chain and marketing of a product as well as

the benefits and functionality of packaging.

The students eligible to participate are thew ones that have

been awarded in a local competition recognized by WPO. For more details and the

easy on-line entry process go to www.WorldStarStudent.org.

Technical Article

Barriers against migration from food packaging

By Philippe Dubois*

Time and again, "toxic food

packaging" appears in the headlines. Consumers are led to believe that

hazardous substances can migrate from the packaging into the food and thus

endanger health. The Joint Industry Group (JIG) of the WPO member, Swiss Packaging Institute (SVI – www.svi-verpackung.ch)

is working with scientific partners to promote food-safe packaging.

Now the project "Migration into food from

closures of boxes made of recycled cardboard with an internal functional

barrier" has been processed and completed.

The Joint Industry Group on Packaging for Food

Contact (JIG) is an association of companies along the value chain led by SVI.

The players join forces in projects and agree that the migration of undesirable

substances from the packaging into the food must be prevented. This should be

done according to market-based and risk-based criteria.

In the discussion about food-safe packaging,

the terms MOSH and MOAH usually come up. These abbreviations are used to

describe two different groups of chemical compounds that occur in mineral oil.

However, it has not yet been proven whether and in what concentrations these

substances can be hazardous to health.

In a first project of the JIG, the barrier

effectiveness of inner bags in boxes made of recycled cardboard was

investigated. As a result, the "SVI Guideline 2015.01_Inner bags" was

published at the beginning of 2016 and received a great deal of attention

throughout Europe.

In the summer of 2015, SVI launched the project

"Barrier Coating for Recycled Cardboard" with the submission and

testing of test materials from various international companies. Nine European

companies supported the project financially and with test materials. A

measurement method was developed under the direction of the Zurich Cantonal

Laboratory. The tests were carried out in Zurich as well as at the

Papiertechnische Stiftung PTS in Heidenau, Germany.

In this project, the effectiveness of barrier

solutions on recycled board through the gas phase was considered. The first

results of the submitted test materials were presented to the project funders

on May 25, 2016. The findings obtained from the first project phase showed that

the developed measurement method needed to be further adapted and developed.

The second phase of the project was

characterized by the investigation of migration through the closures of the

boxes. The development of a measurement method, as well as the requirement that

the migration of all non-evaluated substances from recycled paperboard into

food be below the 1% limit, was summarized in the document "Migration into

food from closures of boxes made of recycled paperboard with an internal

functional barrier." The report was published in the journal:

"Packaging Technology and Science" on June 23, 2021.

In most cases, it concerns the contamination

of food by mineral oils, one of the groups of substances capable of migration.

These can enter the food at various stages of production, with waste paper or

recycled cardboard packaging being one of the main sources of migration into

the food.

The projects mentioned above therefore focused

on the use of barriers in recycled cardboard. With the requirement to

increasingly use recycled plastics in food packaging in the future, new exciting

projects are opening up for the JIG.

*Philippe Dubois is President of the SVI and

Head of the JIG. For more information, contact him by e-mail [email protected].

Technical Article

Microplastics are not a packaging problem

By Philippe Dubois*

Microplastics have been the talk of the town

for a few years now and - as always - packaging is one of the main culprits for

tendentious media and the uninformed public. The Swiss Packaging Institute (SVI

– www.svi-verpackung.ch), a WPO member, briefly

summarizes the known facts here: they show that microplastics are not a

packaging problem.

Since 2015, when the German Federal

Environment Agency warned of "risks to the environment and water bodies

from the use of plastic particles in skin creams, peelings, shower gels and

shampoos", microplastics have increasingly come under the scrutiny of the

media and the public.

Some so-called quality media and various

dubious environmental protection organizations, in their typical

anti-reflection, initially blamed it primarily on gelittered packaging. Today,

based on numerous serious scientific studies and assessments, we have long

known that packaging has practically nothing to do with the problem of

microplastics. Nevertheless, decades of packaging bashing have apparently left

ineradicable notions in the minds of certain journalists and environmentalists.

What is microplastic?

Microplastics are small plastic particles less

than 5 mm (5000 µm) in diameter. A very small proportion of microplastic

particles are produced directly for use and are added as fillers to cosmetics

or toothpaste, for example, and are also used in baby diapers. By far the

largest proportion of microplastic particles, however, is produced by the

decomposition of plastic products or by the decomposition of plastic waste from

households and industry.

How much microplastic ends up in the

environment?

A 2020 study by EBP Schweiz AG commissioned by

the Federal Office for the Environment (FOEN) does not give a specific total

quantity for plastic particles under 5 mm for Switzerland. From a 2018

Fraunhofer Institute study for Germany, about 33,000 tons of plastic particles

under 5 mm can be extrapolated as the annual Swiss emission amount. In 2014,

the EPF Lausanne determined about 91,000 microplastic particles per sq km of

surface in Swiss waters. According to Pro Natura, more recent extrapolations of

water samples have shown that there are 8133 billion microplastic particles in

Lake Zurich. In the Rhine near Basel, more than 200,000 microplastic particles

are said to float per sq km of water surface.

How dangerous is microplastic?

Currently, there is no completed scientific

study of the health risks of microplastic particles for humans. Research is

also in its infancy when it comes to the impact of microplastics on flora and

fauna. In 2019, the Australian University of Newcastle published a shocking

extrapolation from 51 global studies: according to this, a person ingests five

grams of microplastics per week, primarily through food. This is equivalent to

the weight of a credit card. However, there are major regional differences. The

highest levels are found in the USA and Asia. An average value for Switzerland

cannot be derived from the study. How much microplastic a person ingests

depends on where they live, their living conditions and their diet.

Where does microplastic come from?

It is now clear that microplastics originate

to the very smallest extent from packaging. Most microplastics come from

completely different sources, as the FOEN study from 2020 shows: tire abrasion

is by far the largest source in terms of volume. The tire abrasion released

annually is estimated at around 10,700 t for Switzerland.

From sports fields and playgrounds (e.g.

artificial turf), 1120 t of microplastics are released annually via drainage

and resuspension. Around 1000 t of microplastics are generated during the

construction and demolition of buildings, and a further 320 t or so through the

weathering of building facades. In addition to tire abrasion, Swiss roads

contribute around 930 t of shoe sole abrasion, 770 t of road marking abrasion

and 330 t of abrasion from sweeping machines. Washing synthetic textiles also

accounts for a significant proportion: around 650 t of microplastic fibers

enter the wastewater from Swiss washing machines.

The total abrasion from industrial machines is

around 420 t and the abrasion from cleaning plastics is around 200 t. Finally,

so-called littering introduces around 2700 t of macro- and microplastics into

soils and water bodies every year. This mainly includes disposable tableware

and agricultural film, but also packaging. It is not known exactly what

proportion is attributable to packaging. Incidentally, cosmetics only account

for around 15-20 t per year.

Can microplastics in food and cosmetics come

from packaging?

No, basically not. There is practically no

migratable free microplastic in the inner walls of packaging. At most, it is

possible that consumers ingest plastic particles, for example, by extremely

scraping out plastic cups with a knife. There is no risk whatsoever when

packaging is emptied normally. If food and cosmetics are indeed contaminated

with microplastics, then the microplastics originate exclusively from the

filling material.

Conclusion

Microplastics in the environment are a

problem, but their impact on humans, flora and fauna cannot yet be clearly

named and quantified. It is clear that only a very small proportion of the

amount of microplastics released into the Swiss environment each year comes

from littered packaging. And it is also clear that the amount of microplastic

ingested by humans every day does not come from the packaging, but from the

filling material, i.e. from contaminated food and cosmetics.

*Philippe Dubois is President of the SVI and

Head of the JIG. For more information, contact him by e-mail [email protected].

Special Article

Why ‘Smart Packaging’?

By Shruti Parikh*

WPO Corporate Partner, Takeda is a

patient-focused, values-based, R&D-driven global biopharmaceutical company

committed to bringing ‘Better Health and a Brighter Future’ to people

worldwide. Our passion and pursuit of potentially life-changing treatments for

patients are deeply rooted in over 240 years of distinguished history in Japan.

We are committed to bringing better health and a brighter future to patients by

translating science into highly innovative medicines. Our R&D efforts

are focused on four therapeutic areas: Oncology, Rare Diseases, Neuroscience

and Gastroenterology.

The packaging is an essential component for

better product experience and in pharmaceutical industry as it is the first

interface of a brand with the patient. By creating smarter packaging,

brands are able to engage their patients digitally in a new and innovative way

while also promoting adherence. Smart packaging refers to the package that

links the physical world with the digital world, connecting pharmacies,

manufacturers, patients and digital channels. By utilizing new technologies to

become more than just a mere container, allows packages to be more

communicative, dynamic, individualized, and actualized.

Smart Packaging is an umbrella term that

could be used to describe different types of packaging - active packaging and

intelligent packaging. Active packaging focuses on enhancing functionality,

while intelligent packaging puts the focus on communication such as the

packaged content’s status, or other messaging. Broadly, we can classify smart

packaging benefits in three categories: Patient Experience, Product Integrity

and Sustainability.

Patient experience

Last year changed how people experience and

get hold of products and services. The way we get hold of things changed in

2020, and it's becoming more important to deliver positive experience right

through to the last moment. User expectations are driving a number of important

and pressing challenges that pharmaceutical brands need to address. They

include how to get value from existing assets, how to play in the ecosystem

with other business-to-business players, how to deliver an experience to

establish connect with the patient.

Put simply, smart packaging is all about

the end-user and enhancing their experience with a brand and

product. Smart technology offers brands more avenues to stay connected to patients,

to supply more information to patients and HCPs (Health Care Practitioners),

and to keep them engaged with the brand. But it is simply a way of

enhanced communication. If we think about regular product packaging, there’s a

finite amount of space available. Most is given over to key brand details and

product information. This leaves little room to dedicate to content that

deepens your end-users relationship with the brand.

This is a missed opportunity, given that

product packaging garners some of the highest levels of end-user

engagement. 71% of end-users want product packaging to provide

information that’s honest and transparent, so extending the amount of available

space is the key to fostering brand trust.

Digital interface opens various

opportunities for brands, for example:

- Dynamic information sharing: Smart

technology can increase patient engagement by offering a wealth of user

content. Customize information for smaller groups per their language, cultural

or social setup.

- Multimedia sharing: If a picture is worth a

thousand words, imagine the worth of a video! Providing instructions of use,

end of life or reuse instructions through videos has higher recall and

retainability in a user’s mind.

Product integrity

Smart packaging is a game-changer in

product integrity. Instead of a product being scanned at each checkpoint, the

packaging becomes the source of the data. Intelligent applications can extend

shelf life, improve safety, and optimize communication. Simplified inspections,

for example, with a NFC data logger that monitors temperature and freshness

during transport, can increase the product quality, reduce waste, and improve

safety allowing producers to save tremendous time and costs. Additionally,

brands have access to real-time data at any time, from any place and reducing

any risk of losing the product.

In pharmaceutical industry drug products

need to be transported and delivered under strict environmental conditions and

even though providers make use of data loggers, this kind of information cannot

be available in real-time. Smart packages can monitor the condition of a product

and notify whether it is good or compromised using advanced indicators and

sensors, offering providers easy access to quality control.

Sustainability

As sustainability has become integral to

packaging it is necessary that smart packaging designs do align with this

trend. In many ways, useful application of smart packaging is helping the

environment. With smart technology able to detect whether certain drugs are

still safe to use, it could extend the shelf life of a product, reducing drug waste

and providing greater efficiency in the supply chain.

Not only that, embedded information could

also provide the patient with detailed information about how the packaging can

be recycled and even directions to the nearest recycling center.

Packaging is much more than just protecting

the product or displaying static information–it’s an opportunity to create

interactive experiences then enhance product quality and grow brand

rapport. As competition in the industry heats up after the pandemic, it’s

safe to say that the winners are going to be those who take advantage of

emerging technologies to give themselves an edge in a saturated market.

*Shruti Parikh is the Packaging Design Lead

of Takeda Pharmaceuticals (www.takeda.com) based

out of Massachusetts, USA, steering Packaging Design, Sustainable Design and

Patient Engagement Interaction Design capabilities globally. Shruti’s innovation in packaging comes

through the establishment of human factors processes and by employing

user-centered design principles and practices. This approach, in collaboration

with stakeholders, contributes to the creation of value adding solutions and

services that mitigate product misuse, reduce user variability, and enable

better user experiences. *Shruti Parikh is the Packaging Design Lead

of Takeda Pharmaceuticals (www.takeda.com) based

out of Massachusetts, USA, steering Packaging Design, Sustainable Design and

Patient Engagement Interaction Design capabilities globally. Shruti’s innovation in packaging comes

through the establishment of human factors processes and by employing

user-centered design principles and practices. This approach, in collaboration

with stakeholders, contributes to the creation of value adding solutions and

services that mitigate product misuse, reduce user variability, and enable

better user experiences.

For more information on this issue, visit:

News from Corporate Partner

‘Rethinking plastics’, a video that you should watch!

Recently WPO Corporate Partner, BioLogiQ (www.biologiq.com), launched a video in Linked In - https://lnkd.in/dPkEDBYb –

that invite the audience to ‘rethinking plastics’.

The video proposes clear priorities for more eco-friendly plastics:

- (1) plastics should be made from plastics… with a minor portion being made from

renewable feedstocks (mostly to make up for recycling losses);

- (2) plastics should incorporate a “safety mechanism” compatible with nature’s

biodegradation systems in the event they escape recycling and waste management

infrastructures.

While that perfect plastic is yet to be invented, BioLogiQ presents NuPlastiQ

as a “sustainability upgrade” to mainstream PE, PP and PS and bringing them one

step closer to that vision: durable (no accelerated fragmentation), recyclable

and yet more biodegradable, and the most important: available today.

The video also displays, in-depth, recyclability studies demonstrating that,

like paper, it is possible to aspire to have more biodegradable plastics

without disrupting recycling. It also shows some recyclability studies and its

results.

BioLogiQ also believes in a communication program that will enable brands to:

- (a) tell consumers they are utilizing an innovative plant based plastic (with a

label) - packaging level;

- (b) explain that the innovative plant-based plastic has demonstrated potential

for reduced environmental pollution while remaining durable for most uses, making it clear that increased biodegradation does NOT

mean a license to litter. Top priorities continue to be the 3Rs and improved

infrastructure. (partner website).

BioLogiQ is by no means claiming that NuPlastiQ makes PE/PP/PS “perfect”, but

it is a significant step forward. Most importantly: it spearheads the vision of

durable + recyclable + more biodegradable plastics.

For more information about BioLogiQ and its products,

contact Bruno Pereira, Chief Sustainability Officer, by e-mail [email protected].

News from Corporate Partner

Know more about Trayak and the EcoImpact-COMPASS, a life

cycle assessment tool for products and packaging

The new WPO Corporate Partner, Trayak (www.Trayak.com) is a software solutions and consulting company

headquartered in the United States. It provides the leading life cycle

assessment (LCA) tool for products and packaging, EcoImpact-COMPASS, to

a broad range of clients as they embark on their sustainability journeys.

Trayak mission is defined as “to equip our customers with

easy-to-use tools that can be embedded comfortably into their mainstream

development, manufacturing, and launch processes”. And the vision is that all

companies will design and manufacture their portfolios using sustainable strategies

and data-driven analysis.

The name Trayak is loosely defined from Sanskrit as ‘The

Protector’ and this concept is what motivates the commitment to apply LCA,

goal-setting, and cutting-edge design strategies directly into the workflow of

manufacturers and brands across the world. “We strive to protect the earth by

empowering our clients to integrate sustainability into the entire life cycle

of their products and packaging from cradle to grave - through design, materials, manufacturing,

transportation, use, and disposal”, states the company.

This is achieved with tools and expertise to reduce the

environmental impact of companies, pursue stronger sustainability goals,

and better understand the operational tradeoffs that come with design change

using the unique add-on module, SCORE.

Trayak flagship LCA tool, EcoImpact-COMPASS, was initially

developed by the Sustainable Packaging Coalition (SPC) in a collaborative

process with packaging experts, stakeholders, life cycle assessment

professionals, and academia. The life cycle assessment tool sets the industry

standard and is endorsed by organizations such as the Australian Packaging Covenant Organisation,

Packaging Europe, and Walmart's Project Gigaton.

EcoImpact-COMPASS is now fully owned and operated by Trayak

and is a powerful yet user-friendly tool with improvements such as:

- new datasets with specialized packaging materials

and conversion processes;

- integrations into CAD, PLM, ERP, and Spec Management

Systems;

- SCORE module to visualize operational requirements;

- cloud-based software requires no downloads;

- dashboard analytics and simple indicators for easy

reporting.

The company´s goal is to show that implementing sustainable

practices, into a current manufacturing and design process, is not as difficult

as it may seem. Trayak also strives to innovate in the field of life cycle

assessment and product and packaging design while being attentive of the global

context.

For more information, contact Nathan Mckee, Sustainability Analyst, by e-mail [email protected].

|